174

ELECTRONIC TORQUE WRENCH TESTERS

Prices in EURO - VAT not included

3

174

The certificate is issued on the tool as it is

sent, without any repair or adjustment being

made.

They can also calibrate new torque tools if

they need LAT certification as an alternative

to the calibration report supplied.

The pricelist and further documentation is

available on the website

www.prore.it.

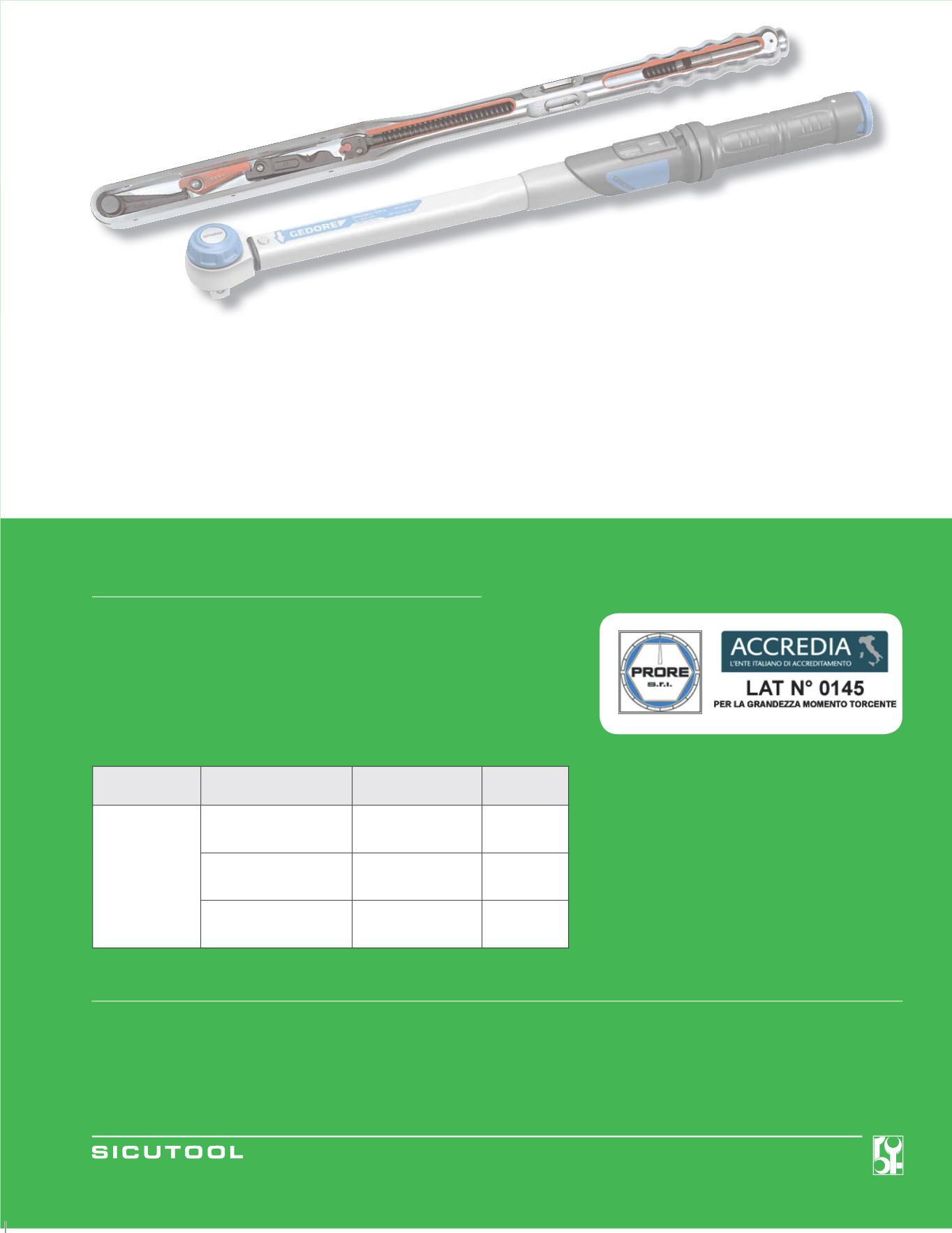

PERIODIC RE-CALIBRATION

WITH ISSUING OF ACCREDIA CERTIFICATION

For all brands of torque meter tools up to a maximum

twisting moment of 1000 Nm Sicutool offers via PRORE

S.r.l. (Calibration Centre accredited LAT 145) a calibration

service with release of LAT certification. The calibration

intervals and relevant expanded uncertainties of

measurement (expressed at a reliability level of 95%) are

outlined in the accreditation table:

Measure

Calbiration

tool

Measuring

range

Expanded

uncertainty

Torque

Torque meter benches

from 0,2 Nm a 10 Nm

from 2 Nm a 100 Nm

from

20 Nm to 1000 Nm

0,5%

0,3%

0,2%

Torque wrenches and

torque screwdrivers

from 0,2 to 1000 Nm

1%

Torque wrenches and direct

reading torque screwdrivers

from 0,2 to 1000 Nm

1%

REPAIR SERVICE

Torque equipment and torque meter benches sold by Sicutool can be sent for repairs, carried out by the manufacturer

(GEDORE).

Repairs are carried out following acceptance of a quote or includes release of a calibration report that certifies correct

operation of the tool.

• 5.3.2

The

re-calibration interval

, as for every test

device, must be determined by the user based on the

type of use of the equipment. Alternatively, a period

may be implemented of

12 months or approx. 5000

cycles

as the value assigned.

For first re-calibration,

the period of validity starts with the first use of the

equipment by the user

.

• 6.4

The

calibration sequence

includes

5

measurements

at

20%

(or the lowest torque value

indicated on the scale) then at

60%

and lastly

100%

of

the maximum torque value.

For

calibration devices

(torque meter benches), the

calibration reports are issued by the manufacturer

according to national legislation or guidelines (DKD-R 3-8

and BS 7882).

Reference to measurement samples is guaranteed and

the metrological characteristics that enable use as primary

samples for calibration of the torque equipment.

Calibration and repair

of torque meter tools

The torque meter tools (torque wrenches and screwdrivers

and calibration devices) are supplied with the

calibration

report

issued by the manufacturer GEDORE.

Main requirements outlined by norm UNI EN ISO 6789

• 5.1.3

The

measurement range

specified is

between

20% and 100%

of the maximum value of the torque

of the respective equipment. The tightening capacity of

the wrenches with a gauge on the Sicutool catalogue

complies with this specification.

• 5.1.5

The

permitted gap

for each calibration point

must be ±4% for equipment with a maximum torque

value >10 Nm or ±6% for equipment with a maximum

torque

d

10 Nm.